... like a canary!

Here I am with fellow RV-12 builder Kim Mitchell from Jefferson, NC, on a nice Fall afternoon on the tarmac of KGEV. The story of my meeting with Kim is worth telling. I have a log cabin in West Jefferson, just a stone throw from KGEV. As I was having trouble finding a hangar in the Raleigh area, I decided to see what the situation was at KGEV. After all, spending a couple of months in the mountain to finish my plane did not feel quite like an exile from my current workshop. While talking to the airport manager and explaining that I was looking to flight test an RV-12, he told me, to my great surprise (and delight) that a gentleman had just built an RV-12 which was now flying and was kept in a hangar at the airport. Needless to say, it did not take me long to find Kim! That was a month ago and last weekend as I was back to watch the Fall colors, Kim kindly invited me for a ride which turned out to be quite a treat.

I was the first passenger in Kim's RV-12. Kim used to fly a Waco that he also built as a wooden kit. His Waco was cruising at 180 Knots and he finds the speed of the RV-12 a bit lacking for his trips between North Carolina and Texas where he spends part of his time. In his search for more speed he is trying to extract any additional knot he can, going to the length of removing the steps of his RV-12 as you can see (or rather not see!) on the pictures. After climbing in this step less -12, it dawned on me why I was the first passenger! (but I will climb again anytime!).

So, how are the Fall colors seen from 4,500 ft high? I have no idea, I was too much focused on how this yellow bird flies and looking at the airport environment and approach, all which might, will, be useful one day, hopefully soon!

Building an RV-12 LSA from a kit by VANs aircraft and learning to fly Light Sport Aircrafts = the full Wright Brothers experience!

Tuesday, October 11, 2011

Sunday, October 2, 2011

Section 31 - Wiring is finished

Well, kind of as the upcoming changes due to the introduction of Skyview avionics led me to drop some of the steps that were clearly intended to the old Dynon glass cockpit. Overall it was a slow summer, I was distracted by a number of events, including the unusual heat. Section 31 spread from August 10 to today. Here is what I have done during the month of September (interrupted lately by a 10 days train trip to New-York, Boston and Maine to visit family and friends).

Friday, September 9, 2011

Playing with control sticks

This is the purpose of page 31-11

I found it fun to go to the bicycle store to buy handle bar grips for the control sticks. I even took one of the control sticks with me and the guy at the shop was intrigued as he had never seen such handlebar.

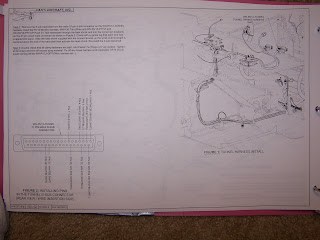

The fun stopped with step 3 which requires to route the wires inside the stick as there is an obstruction at the bottom very visible on figure 2: the sleeve that gets the bushing does not leave a lot of room to guide the wires. The solution: use a fishing line with a sinker (all out of my fishing box!) and use gravity to route the wire from bottom to top. I found this idea on the VAF forum, my usual source of inspiration.

The next challenge was the installation of the control sticks which requires to drill the bushings at 1/4". My drill got stuck several times as it is difficult to secure the bushing tightly without risking to crush it in the vise. I finally got the two sticks installed on a temporary basis as specified but the task was cumbersome with lots of filing to get everything to fit together. Here is where I am tonight: are not my control sticks grips cute?

I found it fun to go to the bicycle store to buy handle bar grips for the control sticks. I even took one of the control sticks with me and the guy at the shop was intrigued as he had never seen such handlebar.

The fun stopped with step 3 which requires to route the wires inside the stick as there is an obstruction at the bottom very visible on figure 2: the sleeve that gets the bushing does not leave a lot of room to guide the wires. The solution: use a fishing line with a sinker (all out of my fishing box!) and use gravity to route the wire from bottom to top. I found this idea on the VAF forum, my usual source of inspiration.

The next challenge was the installation of the control sticks which requires to drill the bushings at 1/4". My drill got stuck several times as it is difficult to secure the bushing tightly without risking to crush it in the vise. I finally got the two sticks installed on a temporary basis as specified but the task was cumbersome with lots of filing to get everything to fit together. Here is where I am tonight: are not my control sticks grips cute?

Tuesday, September 6, 2011

More Wiring

I have finished page 31-10 today, nothing special, just waving wires through bushings, putting terminals at the ends, stripping replaced deburring, working on my stretching while crawling around the fuselage... if only I was 20 years younger! (well, may be not after all, 20 years ago my daughters were in college, I did not have the money!)

Saturday, September 3, 2011

More Wiring and a good surprise!

We spent a few days with friends at our cabin in West Jefferson last week. We have at about 5 miles the great KGEV/Jefferson airport and I went to visit and inquire about hangar availability. My thinking was that given the high cost and low availability of hangars in the Raleigh area, Jefferson might be a good option to finish the plane and test it. While explaining my situation to the airport manager, he told me, to my great surprise (and delight!) that there was a gentleman who had a flying RV-12 in a hangar at the airport. As he kindly gave me his name, I contacted Kim Michell the next day and we had the opportunity to meet right away at my cabin. The RV-12 is the second plane he has built. He built and owned a Falco for several years before building the RV-12 in the last 2 years. Before returning to Raleigh I visited his hangar and saw his nice yellow RV-12. We will have more opportunities to discuss our common interests during my upcoming trips to West Jefferson. I have never imagined I would find an RV-12 owner at Jefferson airport as, in Raleigh, the closest RV-12 flying is more than 1 hour drive away in Carthage.

Here are the pages I have been through during the last three weeks

On Page 31-7, I could only do steps 1, 2, 5 and 8 because I know that the other steps will have to be modified for the Skyview as they are currently designed for the Dynon D100 glass cockpit. I am facing this issue now constantly as I am progressing on the wiring and I am afraid that soon I will have lots of loose end wiring all over. I need to beef-up the documenting on these incomplete steps, on the instructions as well as on the lose wires in limbo themselves.

Here are the pages I have been through during the last three weeks

On Page 31-7, I could only do steps 1, 2, 5 and 8 because I know that the other steps will have to be modified for the Skyview as they are currently designed for the Dynon D100 glass cockpit. I am facing this issue now constantly as I am progressing on the wiring and I am afraid that soon I will have lots of loose end wiring all over. I need to beef-up the documenting on these incomplete steps, on the instructions as well as on the lose wires in limbo themselves.

Wednesday, August 10, 2011

Section 31: "Doin some wirin"...

... As they say in the south!

Just started Section 31:

So, we are starting a new job as an electrician, new challenges, frustrations followed by small victories: this is the life of the VANs kit builder.

After a false start and messing-up a few terminal tabs and terminal blocks with Anne, we decided to skip this page:

Reason to skip the page: Vans has come with a better solution to connect the wing wiring to the fuselage, i.e., a connector rather than the terminal blocks which have been a source of bad contacts with or without wings removal. I confirmed with Vans support that I can skip these steps, waiting for the retrofit which will come with the Skyview release in September.

Page 3 has a lot in it but little challenge.

Page 4, business as usual!

Page 5: Step 2 skipped, pending wing connector as explained earlier

Nothing real tricky, except for the fuel pump clamp attachment in step 4: tight quarters! You will need a special wrench and more...

Page 6:

This is the notorious issue of the Reed Switches that control that the wing stoppers are correctly latched, after wing install. There has been lots of posting on the subject in VAF Forum and I was expecting trouble. Guess what? Here is my VAF Forum final post on the subject after going through this ordeal:

I just spent the last two hours doing step 4, the testing of the reed switches. I was concerned after reading all what was posted on this tricky step and, sure enough, once everything was in place according to instructions, nothing was working. Reading the many postings on this issue did not clarify a lot what the issue is as there is a mix of problems mentioned, including those related to the first kits that got a retrofit later. I got a good lead when I read that it was useful to position the reed switch without the clamp. This allowed me to find out that the switch was kept too far from the arm rest by the cushion clamp. I just removed the rubber on both sides of the clamp where it contacts the arm rest and I reshaped the clamp to fit flat against the arm rest and lo and behold, this did the trick for both sides!

Just started Section 31:

So, we are starting a new job as an electrician, new challenges, frustrations followed by small victories: this is the life of the VANs kit builder.

After a false start and messing-up a few terminal tabs and terminal blocks with Anne, we decided to skip this page:

Reason to skip the page: Vans has come with a better solution to connect the wing wiring to the fuselage, i.e., a connector rather than the terminal blocks which have been a source of bad contacts with or without wings removal. I confirmed with Vans support that I can skip these steps, waiting for the retrofit which will come with the Skyview release in September.

Page 3 has a lot in it but little challenge.

Page 4, business as usual!

Page 5: Step 2 skipped, pending wing connector as explained earlier

Nothing real tricky, except for the fuel pump clamp attachment in step 4: tight quarters! You will need a special wrench and more...

Page 6:

This is the notorious issue of the Reed Switches that control that the wing stoppers are correctly latched, after wing install. There has been lots of posting on the subject in VAF Forum and I was expecting trouble. Guess what? Here is my VAF Forum final post on the subject after going through this ordeal:

I just spent the last two hours doing step 4, the testing of the reed switches. I was concerned after reading all what was posted on this tricky step and, sure enough, once everything was in place according to instructions, nothing was working. Reading the many postings on this issue did not clarify a lot what the issue is as there is a mix of problems mentioned, including those related to the first kits that got a retrofit later. I got a good lead when I read that it was useful to position the reed switch without the clamp. This allowed me to find out that the switch was kept too far from the arm rest by the cushion clamp. I just removed the rubber on both sides of the clamp where it contacts the arm rest and I reshaped the clamp to fit flat against the arm rest and lo and behold, this did the trick for both sides!

I saws that some enlarged the hole and even pushed the switch housing through the hole: no need to do that in my case. I just removed the 1/8 inch of casing indicated in the instructions so that the top of the casing aligns with the center of the hole of the switch. For the rest I followed the instructions.

I hope this will settle the questions raised about the engineering of this safety device: the only problem is the clamp and it is easy to fix.

I hope this will settle the questions raised about the engineering of this safety device: the only problem is the clamp and it is easy to fix.

Here is a picture of the modified clamp with the reed switch inserted:

Note that there is enough rubber left on the clamp to squeeze the reed switch gently but firmly

Note that there is enough rubber left on the clamp to squeeze the reed switch gently but firmly

Saturday, August 6, 2011

Look Ma, no Brakes!

It's what I could have said if I had proceeded with the finishing kit so, what happened?

After starting the wiring section with Anne, my favorite helper, I had to go back into the fuselage section to look-up some details. Oh! surprise! I discovered that I had missed a couple of pages that are dealing with the brakes plumbing. I had found bizarre to have 2 coils of plastic pipes left at the end of the fuselage works plus a few plumbing fixtures but did not worry because I thought that brake plumbing was done when the wheels are assembled in the finishing kit: wrong!

Once again, brake plumbing is a new learning curve to negotiate, different from gas plumbing because the fixtures are not the same. More later once I emerge from this new challenge.

Here are the pages I skipped:

Comments following completion of these brakes tasks:

The major difficulty is getting the fittings set-up as indicated in the first 3 steps of page 27-04. The problem stems from the fact that the plastic tubes have not a consistent inside diameter. For some the brass insert will go in easily for some it's impossible to push it in, even after dunking in boiling water if the sleeve is positioned as indicated. Here is my solution: I slide the sleeve further back and use the nut to push both the sleeve in position and the insert into the tube, whichever comes first. The rest of the job went well, I had only one question left about torquing the compression fittings after they installed are finger tight. Tony Tessitore reminded me that section 5 specifies page 5-12 to add one more turn after finger tight screwed: always read section 5 when dealing with new technology/process... and thanks Tony!

After starting the wiring section with Anne, my favorite helper, I had to go back into the fuselage section to look-up some details. Oh! surprise! I discovered that I had missed a couple of pages that are dealing with the brakes plumbing. I had found bizarre to have 2 coils of plastic pipes left at the end of the fuselage works plus a few plumbing fixtures but did not worry because I thought that brake plumbing was done when the wheels are assembled in the finishing kit: wrong!

Once again, brake plumbing is a new learning curve to negotiate, different from gas plumbing because the fixtures are not the same. More later once I emerge from this new challenge.

Here are the pages I skipped:

Comments following completion of these brakes tasks:

The major difficulty is getting the fittings set-up as indicated in the first 3 steps of page 27-04. The problem stems from the fact that the plastic tubes have not a consistent inside diameter. For some the brass insert will go in easily for some it's impossible to push it in, even after dunking in boiling water if the sleeve is positioned as indicated. Here is my solution: I slide the sleeve further back and use the nut to push both the sleeve in position and the insert into the tube, whichever comes first. The rest of the job went well, I had only one question left about torquing the compression fittings after they installed are finger tight. Tony Tessitore reminded me that section 5 specifies page 5-12 to add one more turn after finger tight screwed: always read section 5 when dealing with new technology/process... and thanks Tony!

Subscribe to:

Posts (Atom)