Having been slowed down all Summer and facing now Winter, I have decided to postpone my move to an airport hangar until late Winter or early Spring. One of the delaying factors is the release of the new avionics kit based on Dynon's Skyview which was initially expected for July but has been delayed one month every month since. To be fair VANs never committed for a release date. They are facing a complex problem because they have several changes to do in parallel and they are dealing with the E-LSA certification of a retrofit for the first time. This delay is not that of a problem for me because I still have a lot to do on the finishing kit but some fellow builders are blocked at a time they thought they would be flying - how frustrating! I therefore decided to do a maximum in my workshop to cope with this situation and the first conclusion I drew was that I needed a large slab in front of my workshop to perform the wings as well as empennage fittings that initially I had planned to do in an airport hangar.

How to build a taxiway?

First build a drive way and then taxi an airplane on it!

Here is my taxiway under construction:

And here it is completed:

Now the RV-12 is on its stands, ready to move outside!

Building an RV-12 LSA from a kit by VANs aircraft and learning to fly Light Sport Aircrafts = the full Wright Brothers experience!

Monday, November 14, 2011

Friday, November 4, 2011

We have a flap control handle...

... but no flaps connected yet!

This is the fruit of yesterday and today's labor:

The funny thing is that in the Allegro that I fly, the trim is manual and the flaps controlled by an electric motor while on the R-12 it's just the opposite. While I like the direct manual control of the flaps in the RV-12, I don't like the electric trim. In the Allegro, the position of the trim button tells you where your trim tab is set, an information that you don't have in the RV-12.

Also worked a bit on the rest of page 32-08:

As I was working on the torque tube spacers, I found bizarre that I had to drill #12 a hole in which an LP4-3 was supposed to go (usually we drill #30 for LP4-3). I did a search on VAF forum and, sure enough, the issue had been raised ... two years ago by John Peck. The answer made sense: the rivet is just a temporary holder as the spacers are glued to the torque tube.

This is the fruit of yesterday and today's labor:

The funny thing is that in the Allegro that I fly, the trim is manual and the flaps controlled by an electric motor while on the R-12 it's just the opposite. While I like the direct manual control of the flaps in the RV-12, I don't like the electric trim. In the Allegro, the position of the trim button tells you where your trim tab is set, an information that you don't have in the RV-12.

Also worked a bit on the rest of page 32-08:

As I was working on the torque tube spacers, I found bizarre that I had to drill #12 a hole in which an LP4-3 was supposed to go (usually we drill #30 for LP4-3). I did a search on VAF forum and, sure enough, the issue had been raised ... two years ago by John Peck. The answer made sense: the rivet is just a temporary holder as the spacers are glued to the torque tube.

Wednesday, November 2, 2011

Page 32-06

Completed, with some pain caused by the paint:

Not a big deal but this may save some future builders the aggravation I went through yesterday.

Steps 4 and 5 are about attaching the WD-1215 Flapperon Torque arms which is happening in very tight quarters. In step 4 I found quickly that the AN3 bolt would not pass through the holes of WD-1215 because of the paint. A bit of filing solved the problem. Unfortunately, after struggling through the attachment both WD-1215, I found that, in step 5, I had the same problem for attaching the WD-1215 to the pushrod assemblies! There is no way that you can file the inside of these holes once the WD-1215 are attached: I had the disassemble the two WD-1215 to clear the holes!

... and I consider myself lucky that the 4 AN-960 that were superglued to the brackets stayed in place through the two installations.

Not a big deal but this may save some future builders the aggravation I went through yesterday.

Steps 4 and 5 are about attaching the WD-1215 Flapperon Torque arms which is happening in very tight quarters. In step 4 I found quickly that the AN3 bolt would not pass through the holes of WD-1215 because of the paint. A bit of filing solved the problem. Unfortunately, after struggling through the attachment both WD-1215, I found that, in step 5, I had the same problem for attaching the WD-1215 to the pushrod assemblies! There is no way that you can file the inside of these holes once the WD-1215 are attached: I had the disassemble the two WD-1215 to clear the holes!

... and I consider myself lucky that the 4 AN-960 that were superglued to the brackets stayed in place through the two installations.

Page 32-07

Completed

Saturday, October 22, 2011

Looking at Falls Colors from Above... Again?

The weather was so beautiful, we could not resist heading back to Appalachian Mountains for a last look at the Fall colors. Now I can't go to West Jefferson without paying a visit to KGEV, and what do I find there?

My fellow builder Kim Mitchell's yellow bird, always ready for a spin (just a metaphor!)

Here we are "Ashe county, experimental RV12 980 Kilo Mike, departing runway 10, Ashe county"

... and a couple of minutes later:

We are on our way to Grand Father mountain (the tall mountain at 1 O'clock) in smooth air with a fantastic view; we literally own the class Echo airspace at 6500 feet while the poor souls on the roads under us are queued on the Blue Ridge Parkway. The Rotax is humming, the bird as steady as an airliner, Kim says: it does not get any better than that and I believe him!

I could have taken more pictures but Kim gave me the plane to fly, hey, it really got better for me!

My fellow builder Kim Mitchell's yellow bird, always ready for a spin (just a metaphor!)

Here we are "Ashe county, experimental RV12 980 Kilo Mike, departing runway 10, Ashe county"

... and a couple of minutes later:

We are on our way to Grand Father mountain (the tall mountain at 1 O'clock) in smooth air with a fantastic view; we literally own the class Echo airspace at 6500 feet while the poor souls on the roads under us are queued on the Blue Ridge Parkway. The Rotax is humming, the bird as steady as an airliner, Kim says: it does not get any better than that and I believe him!

I could have taken more pictures but Kim gave me the plane to fly, hey, it really got better for me!

Thursday, October 20, 2011

Section 32: Flight Controls on the way

Here is what was covered over the last weeks:

The work at the bottom of the cockpit becomes more and more cramped: the installation of the control sticks pushrod assemblies as described in page 32-05 is a challenge!

One pushrod on its way:

Note that I had to disassemble the control stick to attach the pushrod.

Here the two assemblies are in place after a long struggle!

The work at the bottom of the cockpit becomes more and more cramped: the installation of the control sticks pushrod assemblies as described in page 32-05 is a challenge!

One pushrod on its way:

Note that I had to disassemble the control stick to attach the pushrod.

Here the two assemblies are in place after a long struggle!

Tuesday, October 11, 2011

Watching Appalachian Falls Colors From Above

... like a canary!

Here I am with fellow RV-12 builder Kim Mitchell from Jefferson, NC, on a nice Fall afternoon on the tarmac of KGEV. The story of my meeting with Kim is worth telling. I have a log cabin in West Jefferson, just a stone throw from KGEV. As I was having trouble finding a hangar in the Raleigh area, I decided to see what the situation was at KGEV. After all, spending a couple of months in the mountain to finish my plane did not feel quite like an exile from my current workshop. While talking to the airport manager and explaining that I was looking to flight test an RV-12, he told me, to my great surprise (and delight) that a gentleman had just built an RV-12 which was now flying and was kept in a hangar at the airport. Needless to say, it did not take me long to find Kim! That was a month ago and last weekend as I was back to watch the Fall colors, Kim kindly invited me for a ride which turned out to be quite a treat.

I was the first passenger in Kim's RV-12. Kim used to fly a Waco that he also built as a wooden kit. His Waco was cruising at 180 Knots and he finds the speed of the RV-12 a bit lacking for his trips between North Carolina and Texas where he spends part of his time. In his search for more speed he is trying to extract any additional knot he can, going to the length of removing the steps of his RV-12 as you can see (or rather not see!) on the pictures. After climbing in this step less -12, it dawned on me why I was the first passenger! (but I will climb again anytime!).

So, how are the Fall colors seen from 4,500 ft high? I have no idea, I was too much focused on how this yellow bird flies and looking at the airport environment and approach, all which might, will, be useful one day, hopefully soon!

Here I am with fellow RV-12 builder Kim Mitchell from Jefferson, NC, on a nice Fall afternoon on the tarmac of KGEV. The story of my meeting with Kim is worth telling. I have a log cabin in West Jefferson, just a stone throw from KGEV. As I was having trouble finding a hangar in the Raleigh area, I decided to see what the situation was at KGEV. After all, spending a couple of months in the mountain to finish my plane did not feel quite like an exile from my current workshop. While talking to the airport manager and explaining that I was looking to flight test an RV-12, he told me, to my great surprise (and delight) that a gentleman had just built an RV-12 which was now flying and was kept in a hangar at the airport. Needless to say, it did not take me long to find Kim! That was a month ago and last weekend as I was back to watch the Fall colors, Kim kindly invited me for a ride which turned out to be quite a treat.

I was the first passenger in Kim's RV-12. Kim used to fly a Waco that he also built as a wooden kit. His Waco was cruising at 180 Knots and he finds the speed of the RV-12 a bit lacking for his trips between North Carolina and Texas where he spends part of his time. In his search for more speed he is trying to extract any additional knot he can, going to the length of removing the steps of his RV-12 as you can see (or rather not see!) on the pictures. After climbing in this step less -12, it dawned on me why I was the first passenger! (but I will climb again anytime!).

So, how are the Fall colors seen from 4,500 ft high? I have no idea, I was too much focused on how this yellow bird flies and looking at the airport environment and approach, all which might, will, be useful one day, hopefully soon!

Sunday, October 2, 2011

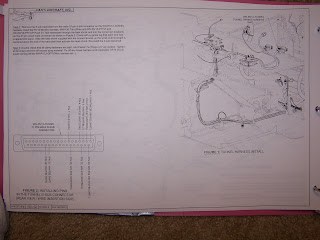

Section 31 - Wiring is finished

Well, kind of as the upcoming changes due to the introduction of Skyview avionics led me to drop some of the steps that were clearly intended to the old Dynon glass cockpit. Overall it was a slow summer, I was distracted by a number of events, including the unusual heat. Section 31 spread from August 10 to today. Here is what I have done during the month of September (interrupted lately by a 10 days train trip to New-York, Boston and Maine to visit family and friends).

Subscribe to:

Posts (Atom)