Although I did not post on this blog in more than a month, a lot has happened and progress was made.

Beside the work on the canopy, I was one of the 16,000 participants to the Sebring LSA Show in January. It was an opportunity to attend a Dynon class on the Skyview glass cockpit which will equip my RV-12. I came back convinced that the RV-12 is one of the best Light Sport airplanes on the market and definitely the best Kit. I also found that two major components of my plane: the Rotax engine and the Dynon Skyview glass cockpit have been pervasively adopted by the LSA industry with their competitors just nibbling at the niche market's margin.

On the flying side I flew for the first time into Class C's RDU airport (which is just 5 miles from my home, although I had to drive first 40 miles to KTTA where I flew from on the Allegro). On take off from RDU I was behind a Boeing 727... I felt so tiny!

I also found a plane for transition training in Salisbury, NC. It is a SportCruiser, a low wings LSA that flies just like the RV-12: same engine, same weight, glass cockpit, with light controls and differential braking. I took my first flight with Davis Amos (owner of Amos aviation) as CFI and found it much easier to fly than the Allegro. With 10 Knots of cross wind I had no problem on landing although it was my first flight.

Back to the Kit building, as of today my canopy work is finished as shown in the pictures below. There is lots at stake when working on the plexiglass in a cold workshop and I therefore proceeded very carefully which explains the weeks it took to complete.

Here the canopy has been drilled and positioned for screwing and riveting. The clearances are measured in 1/16 and 1/32 of an inch a very tedious and precise phase with lots of grinding, fitting, regrinding, etc...

This is all done, no more clecos!

A view from the inside, canopy closed:

These are the tools of the trade:

A little secret learned from Mark Glazer (EAA 1114): no filing, no sawing, just grinding with fine grit paper or scotchbrite disks, all drilled holes deburred with tiny fast spinning grinding stones.

A little help to keep the plastic warm: a thermostated radiator inside the closed cockpit:

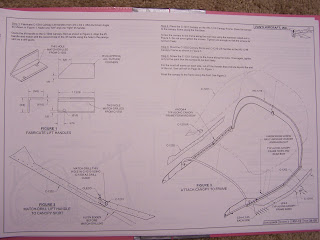

Here are the instruction pages involved and now checked:

A note to the builders:

When fastening the canopy to the rear bow, I faced a problem not mentioned in the instructions: The holes in the rear bow that were punched in the factory are slightly too small for the screws. This results in the screws acting like a tap although the fastening is provided by a nut. This results in the screw head not always being flat on the plastic surface. After calling VANs, I was instructed to enlarge the holes with a #29 drill bit... one more drilling, canopy removing, deburring, canopy mounting cycle!

Want to know how many such cycles I had to go through? Ask my wife Michèle, she helped me carry the canopy on and off!

Building an RV-12 LSA from a kit by VANs aircraft and learning to fly Light Sport Aircrafts = the full Wright Brothers experience!

Sunday, February 12, 2012

Friday, January 6, 2012

She is on her legs! (*)

(*) From a French language/culture stand point, I feel it a bit shocking for my RV-12 to be called a "she" but I am told that, as an air ship, it is the right way to call her. Darn Brits!

Well, kind of on her legs:

As you can see, I am missing the front wheel and here is the culprit:

The axle diameter is 625thou vs the bearing hole of 618thou: Aurora, we have a problem!

I decidedly had no luck with the landing gear, after the bad tire, a bad wheel. I understand that these are problems with the part suppliers of VANs but I would advise VANs to put some pressure on those suppliers who have quality problems (earlier this year there was a more serious problem with the welding of flaperon actuators, also produced outside VANs).

I am waiting from VANs after they contact the supplier MATCO but I see a new wheel delivery in my future.

01/11/2012 update:

After investigation VAN's determined that the axle was not machined to the correct dimensions. I received a new axle and everything is now in order, we are on three wheels now!

The installation of the nose gear wheel will conclude section 35 per the instruction sheets below

Well, kind of on her legs:

As you can see, I am missing the front wheel and here is the culprit:

The axle diameter is 625thou vs the bearing hole of 618thou: Aurora, we have a problem!

I decidedly had no luck with the landing gear, after the bad tire, a bad wheel. I understand that these are problems with the part suppliers of VANs but I would advise VANs to put some pressure on those suppliers who have quality problems (earlier this year there was a more serious problem with the welding of flaperon actuators, also produced outside VANs).

I am waiting from VANs after they contact the supplier MATCO but I see a new wheel delivery in my future.

01/11/2012 update:

After investigation VAN's determined that the axle was not machined to the correct dimensions. I received a new axle and everything is now in order, we are on three wheels now!

The installation of the nose gear wheel will conclude section 35 per the instruction sheets below

Tuesday, January 3, 2012

The left gear is in

As for the right gear, I needed help and even with two pairs of hands, there was quite a bit of crawling and strugling to get the bolts trough and securely torqued to specs. The second pair of hands was provided by François again. Here he is trying to put a wheel on (or is he just warming his butt? - it was a cold day as the heater behind him shows):

Monday, December 19, 2011

One leg down, one to go!

It was quite a struggle and it took a few hours with the help of François.

Here is what was at stake:

Fitting the right landing gear into this tight space

Here it is done but aligning the bolts at the top of the picture with the holes is very awkward due to the lack of space to move the clamp and the lack of visibility. Two people have to be involved, one lying under the plane to move the clamp with the bolts and one looking from the top to guide the bolts into the holes.

This is the end result of the struggle: one gear leg in place, ready to receive its wheel.

One of the most difficult tasks since I started building. I felt lucky to be able to complete it without having to remove the rivets heads that were in the way as some builders did. Definitely not a one man job, thank you François for the help!

Let's wait until next year to take care of the left gear!

(Plus I have to visit my daughters during the holiday, one in New York and one in Washington DC, this will be a good break and well deserved too)

Here is what was at stake:

Fitting the right landing gear into this tight space

Here it is done but aligning the bolts at the top of the picture with the holes is very awkward due to the lack of space to move the clamp and the lack of visibility. Two people have to be involved, one lying under the plane to move the clamp with the bolts and one looking from the top to guide the bolts into the holes.

This is the end result of the struggle: one gear leg in place, ready to receive its wheel.

One of the most difficult tasks since I started building. I felt lucky to be able to complete it without having to remove the rivets heads that were in the way as some builders did. Definitely not a one man job, thank you François for the help!

Let's wait until next year to take care of the left gear!

(Plus I have to visit my daughters during the holiday, one in New York and one in Washington DC, this will be a good break and well deserved too)

Saturday, December 10, 2011

Wheeling and Dealing

This is what I discovered while mounting the tire on my front wheel:

This spot is diametrically opposed to the one above:

I have two more tires to mount but on inspection they do not seem to have this problem.

I have referred this to VANs and am waiting for their answer which hopefully will be a return.

As of December 17:

Vans sent me a new tire that I received today, no cost involved. They also asked me to return the bad tire to the tire vendor which I did. Issue closed.

What an RV-12 wheel is made of:

And don't imagine that it's easy to get there: the wheel comes all assembled and you have to pick it apart to mount the tire! Interestingly, there is no instruction to disassemble, in doubt I had to call Vans to make sure I was doing it right. Oh well, may be I'm not that smart!

At least I will know what keeps me rolling!

This spot is diametrically opposed to the one above:

I have two more tires to mount but on inspection they do not seem to have this problem.

I have referred this to VANs and am waiting for their answer which hopefully will be a return.

As of December 17:

Vans sent me a new tire that I received today, no cost involved. They also asked me to return the bad tire to the tire vendor which I did. Issue closed.

What an RV-12 wheel is made of:

And don't imagine that it's easy to get there: the wheel comes all assembled and you have to pick it apart to mount the tire! Interestingly, there is no instruction to disassemble, in doubt I had to call Vans to make sure I was doing it right. Oh well, may be I'm not that smart!

At least I will know what keeps me rolling!

Friday, December 9, 2011

RV-12 going places

A fellow UK builder from Scotland (see his builder's log: http://www.mykitlog.com/grmps) shot these videos while flying over France and Italy:

(The camera is a wide angle positioned on the VS)

http://www.youtube.com/watch?v=ofOC-qKF1DU

http://youtu.be/_FYv045auC4

http://youtu.be/0NFhc__pzKY

Now, this is traveling light but in style!

(The camera is a wide angle positioned on the VS)

http://www.youtube.com/watch?v=ofOC-qKF1DU

http://youtu.be/_FYv045auC4

http://youtu.be/0NFhc__pzKY

Now, this is traveling light but in style!

Saturday, December 3, 2011

Open Shop for EAA 1114

I put the wings on for the second time to show my RV-12 to my fellow EAA Chapter 1114 members. I enjoyed exercising some "bragging rights" after one and a half year of building (although I also learned to eat lots of humble pie during this period). We were fortunate to have a wonderful weather for December and I got all the help I needed to move my stuff around. I think that this initiative to open builder's workshop for our chapter's members is a great motivator both for builders and for members who wish to start building one day. One reason among many others that chapter 1114 is among the most dynamic EAA chapters in the country.

Subscribe to:

Posts (Atom)